Antioxidant BHT 264

CAS:128-37-0

Purity:99%

Contact Now

We will contact you as soon as possible

Your Location:Home >Products >High-Tech New Material >77-94-1

Product Details

|

Outline |

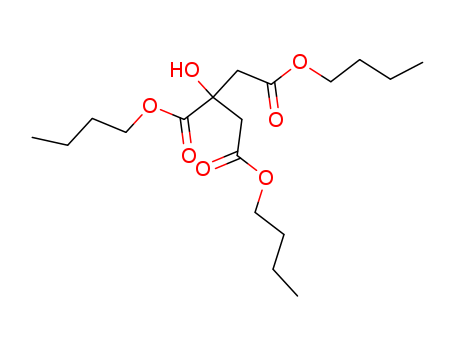

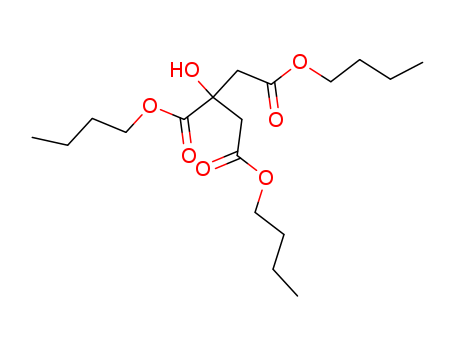

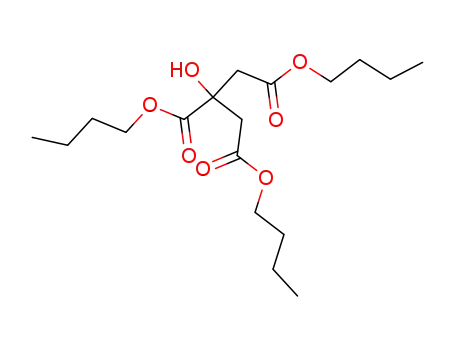

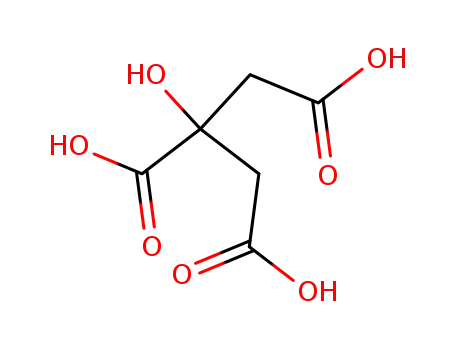

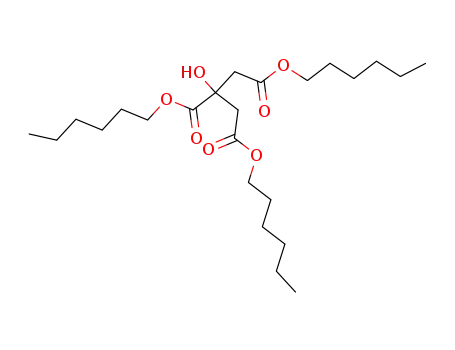

Tributyl citrate (TBC) is a good environmental plasticizers, lubricants. At room temperature, it is non-toxic, it has fruit flavor, it is colorless oily liquid. Boiling point is 170℃ (133.3Pa), flash point (open cup) is 185℃. It is soluble in most organic solvents. Volatile is small, it has good compatibility with the resin, it has high efficiency in plastification, in Europe and other countries it is allowed for food packaging and medical products, as well as children's soft toys, pharmaceuticals, medical products, flavors and fragrances, cosmetics manufacturing and other industries.Products can be given a good cold resistance, water resistance and mildew resistance. The product which is resin plasticized can exhibit good transparency and low temperature flexural properties, and has low volatility and low extraction resistance in different media, thermal stability, it does not change color when be heat. The product which prepared by lubricating oil can have good lubricating properties. |

|

New non-toxic plasticizer |

The most commonly used plasticizer is phthalate esters industrially, because it can induce cancer, the use in foreign countries has been controlled strictly , China has also formulated relevant laws and regulations, and will phase out its use in food packaging materials, medical appliances toys . Tributyl citrate (TBC) is a new non-toxic plasticizer, because it has good compatibility, high plasticizing efficiency, non-toxic and less volatile, weather resistance and other characteristics of broad interest, it is used as the preferred alternative green products in place of phthalic dimethyl esters. With the growing awareness of environmental protection and improvement of environmental regulations, the development and production of tributyl citrate has excellent prospects. Tributyl citrate is usually caused with citric acid and n-butanol in the presence of catalyst by esterifying, the conventional catalyst is concentrated sulfuric acid, although its low price, high catalytic activity, it can cause serious corrosion for equipment, post-processing process is complex, the select of reaction is poor, environmental pollution is serious and other defects, and thus the work of seeking alternative catalysts in place of concentrated sulfuric acid is very active, some better catalytic effect of the catalyst has been found: [Sodium bisulfate catalytic synthesis of tributyl citrate] Monohydrate Sodium hydroxide is a strong ionic compounds, the study found that it is soluble in water, aqueous solution is strongly acidic but it is insoluble in organic acids and alcohols reaction system, it can be used as a catalyst for esterification, studies show that the catalyst has a high activity catalytic, good stability, high yield, easy separation, convenient synthesis method, no corrosion, no pollution and other advantages. [Synthesis of solid superacid catalyst] Superacid is an acid, which the strength is greater than 100% sulfuric acid. Studies have shown that using it as a catalyst for the esterification reaction has good selectivity, fast response, high yield, easy separation, ease of operation, and the catalyst is stable, reusable, non-corrosive, non-polluting, it is a kind of promising catalyst. [Synthesis of p-toluenesulfonic acid catalysis] Toluenesulfonic acid is a strong organic acid, it can be used to instead of concentrated sulfuric acid as the esterification catalyst, and the corrosion for equipment and waste pollution is much smaller than that of sulfuric acid, it is also high activity and selectivity, cheap, dosage less, good product color, it is fit catalyst for industrial production. [Miscellaneous catalytic synthesis of tributyl citrate] Heteropolyacid is a multi-proton acid, the stronger of acidity, the more conducive to the formation of salt, it provide more favorable conditions for other nucleophilic attack, thus it speeds up the rate of the esterification reaction. It is non-volatile, the thermal stability is well, it also cause less pollution and can reduce equipment corrosion, it is an ideal esterification catalyst. The above information is edited by the lookchem of Wang Xiaodong. |

|

Production Methods |

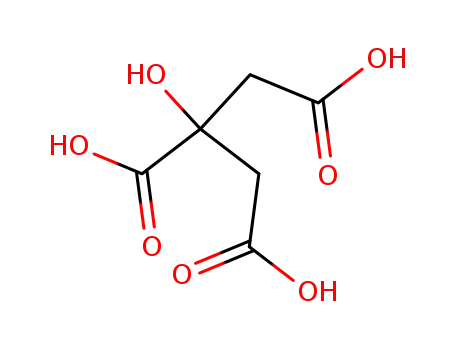

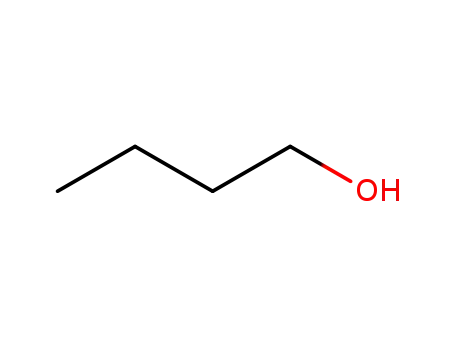

Tributyl citrate is prepared by the esterification of citric acid with butanol. |

|

Pharmaceutical Applications |

Tributyl citrate is used to plasticize polymers in formulated pharmaceutical coatings. The coating applications include capsules, tablets, beads, and granules for taste masking, immediate release, sustained-release, and enteric formulations. |

|

Safety |

Tributyl citrate is used in oral pharmaceutical formulations. It is generally regarded as an essentially nontoxic and nonirritating material. However, ingestion of large quantities may be harmful. LD50 (cat, oral): >50 mL/kg LD50 (mouse, IP): 2.9 g/kg LD50 (rat, oral): >30 mL/kg |

|

storage |

Tributyl citrate should be stored in well-closed containers in a cool, dry location at temperatures not exceeding 38℃. When stored in accordance with these conditions, tributyl citrate is a stable material. |

|

Incompatibilities |

Tributyl citrate is incompatible with strong alkalis and oxidizing materials. |

|

Regulatory Status |

Approved in the USA for indirect food contact in food films. Included in the Canadian List of Acceptable Non-medicinal Ingredients. |

|

Chemical properties |

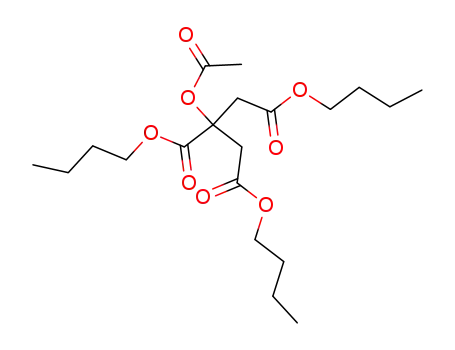

It is colorless, oily liquid, slightly scented. It is insoluble in water, soluble in methanol, acetone, carbon tetrachloride, acetic acid, castor oil, mineral oil, organic solvents. |

|

General Description |

Tributyl citrate is an ester of citric acid. It is used to plasticize polymers for coating solid drug dosage forms, tablets and capsules.Certified pharmaceutical secondary standards for application in quality control provide pharma laboratories and manufacturers with a convenient and cost-effective alternative to pharmacopeia primary standards. |

InChI:InChI=1/C18H32O7/c1-4-7-10-23-15(19)13-18(22,17(21)25-12-9-6-3)14-16(20)24-11-8-5-2/h22H,4-14H2,1-3H3

A series of polyaniline supported hetero...

The invention provides a novel cyclohexy...

The invention discloses a citrate plasti...

The invention discloses a citrate plasti...

The present invention relates to a plast...

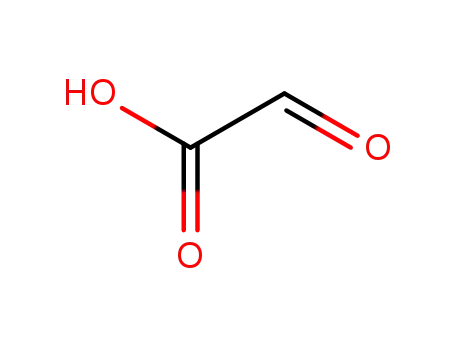

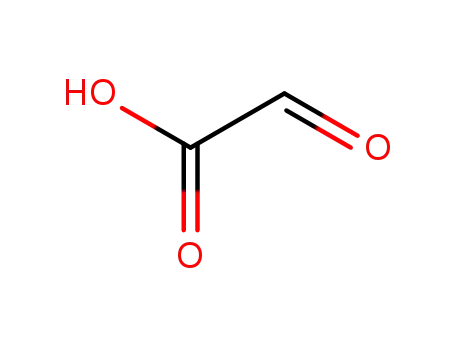

Glyoxilic acid

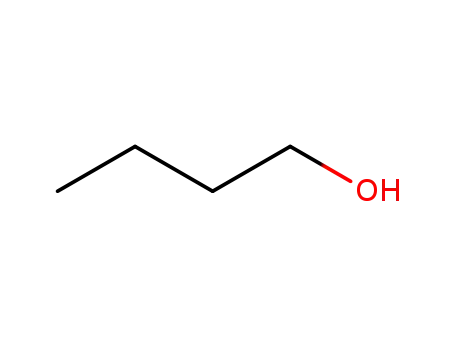

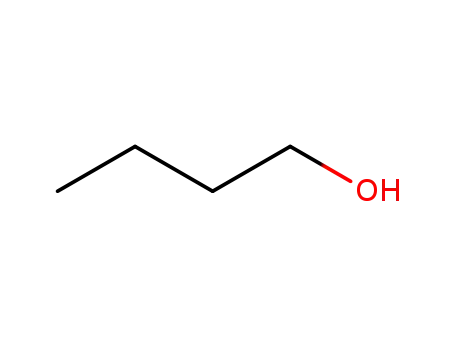

butan-1-ol

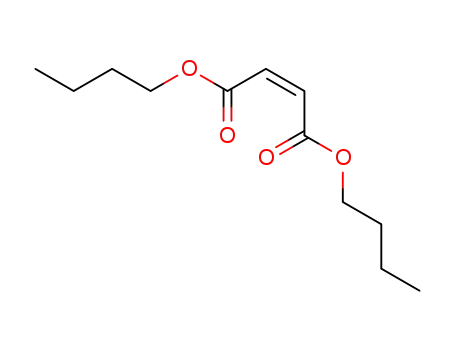

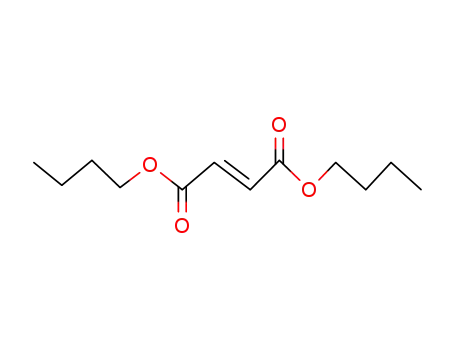

Dibutyl maleate

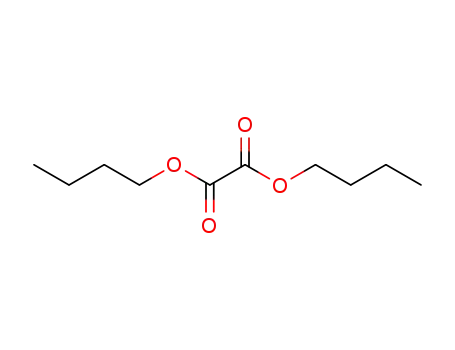

di-n-butyl oxalate

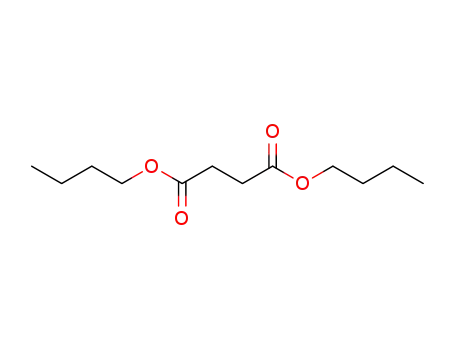

dibutyl succinate

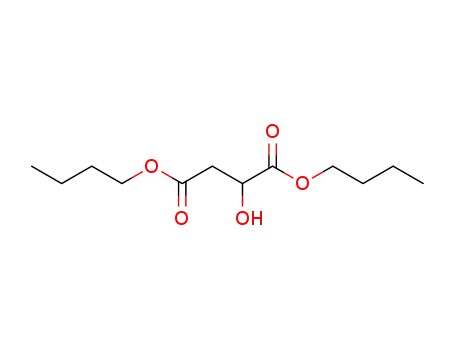

L-(-)-di-n butyl malate

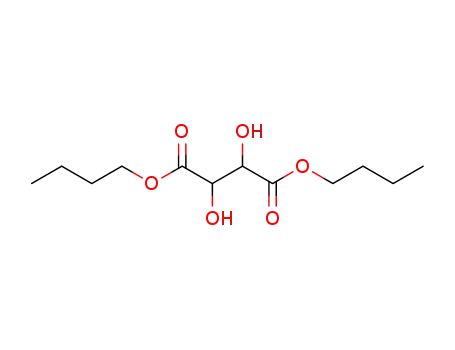

dibutyl tartrate

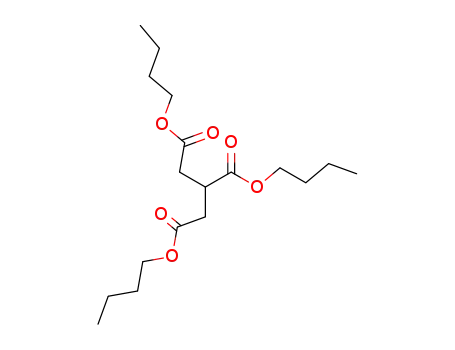

propane-1,2,3-tricarboxylic acid tributyl ester

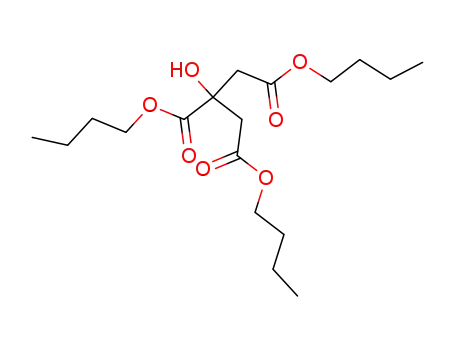

Citroflex-4

dibutyl fumarate

C11H20O5

C12H22O4S3

| Conditions | Yield |

|---|---|

|

Glyoxilic acid;

With

sodiumsulfide nonahydrate;

In

water;

at 90 ℃;

for 168h;

butan-1-ol;

With

hydrogenchloride;

at 90 ℃;

for 2h;

|

citric acid

butan-1-ol

Citroflex-4

| Conditions | Yield |

|---|---|

|

With

1,3-propanesultone; sulfuric acid; manganese(II) acetate; Cycloheximide;

In

water; toluene;

at 65 - 100 ℃;

for 31h;

Temperature;

Ionic liquid;

|

98.6% |

|

With

dimesitylammonium pentafluorobenzenesulfonate;

In

n-heptane;

at 80 ℃;

for 24h;

|

97% |

|

With

3H(1+)*O40SiW12(4-)*C21H22O3PS(1+);

Concentration;

Reflux;

Dean-Stark;

|

97.5% |

|

With

triflic acid on silica-encapsulated superparamagnetic iron oxide nanoparticles;

In

neat (no solvent);

at 90 ℃;

for 1.58333h;

Time;

Reagent/catalyst;

Catalytic behavior;

Flow reactor;

Green chemistry;

|

96% |

|

With

sulfonic acid resin;

for 5h;

Reagent/catalyst;

Heating;

|

96.73% |

|

With

[3-(1-methylimidazolium-3-yl)propane-1-sulfonate]3PW12O40;

at 130 ℃;

for 3h;

|

95.4% |

|

With

glucose-diphenylaminium tosylate-derived carbon solid acid (GDTCSA);

In

n-heptane;

at 80 ℃;

for 24h;

|

95% |

|

citric acid;

With

choline chloride;

at 80 ℃;

for 3h;

Inert atmosphere;

butan-1-ol;

at 130 ℃;

Concentration;

Temperature;

|

95.3% |

|

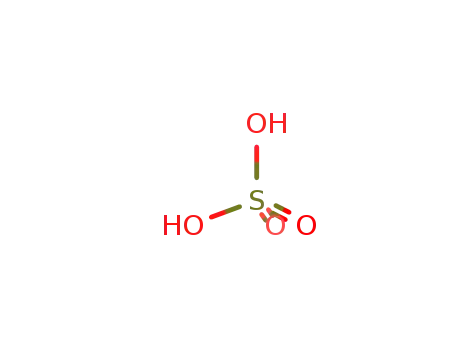

sulfuric acid;

at 95 - 143 ℃;

for 6.33333h;

|

94.1% |

|

With

sulfonated graphene;

In

neat (no solvent);

at 120 ℃;

for 4h;

|

93% |

|

With

toluene-4-sulfonic acid;

In

toluene;

at 90 - 110 ℃;

for 4h;

|

84.4% |

|

With

sulfuric acid; copper(II) sulfate;

|

|

|

With

sulfuric acid;

at 175 ℃;

Kontinuierliches Verfahren zur Herstellung;

|

|

|

With

sulfuric acid; 1,2-dichloro-ethane;

|

|

|

for 3h;

SO42-/zirconium-containing mesoporous molecular sieve;

|

|

|

With

Poly(VMPS)-PW;

at 130 ℃;

for 3h;

Neat (no solvent);

|

|

|

With

Tetrahydrofurfuryl alcohol; methanesulfonic acid;

In

toluene;

Concentration;

Reflux;

|

|

|

With

aluminum oxide; silica gel; tin(IV) oxide;

In

water;

at 130 - 160 ℃;

Concentration;

|

|

|

With

pyrographite; toluene-4-sulfonic acid;

at 175 ℃;

under 187.519 Torr;

Inert atmosphere;

Green chemistry;

|

|

|

at 100 - 150 ℃;

Green chemistry;

|

|

|

With

20% polyaniline supported on phosphotungstic acid;

at 140 ℃;

for 3.5h;

Reagent/catalyst;

Temperature;

Green chemistry;

|

|

|

With

toluene-4-sulfonic acid;

In

cyclohexane; water;

at 120 ℃;

for 4h;

|

|

|

With

toluene-4-sulfonic acid;

In

cyclohexane; water;

at 120 ℃;

for 4h;

|

citric acid

butan-1-ol

sulfuric acid

Glyoxilic acid

tri-n-hexyl citrate

acetyltributyl citrate